By Tanya Nanetti

Milk is familiar to most of us. Not just a drink for children, it’s also often consumed by adults and is of course one of the key ingredients at cafés. But you may be unfamiliar with the processing that milk undergoes before reaching the market, and one such process is homogenization.

The Process of Homogenization

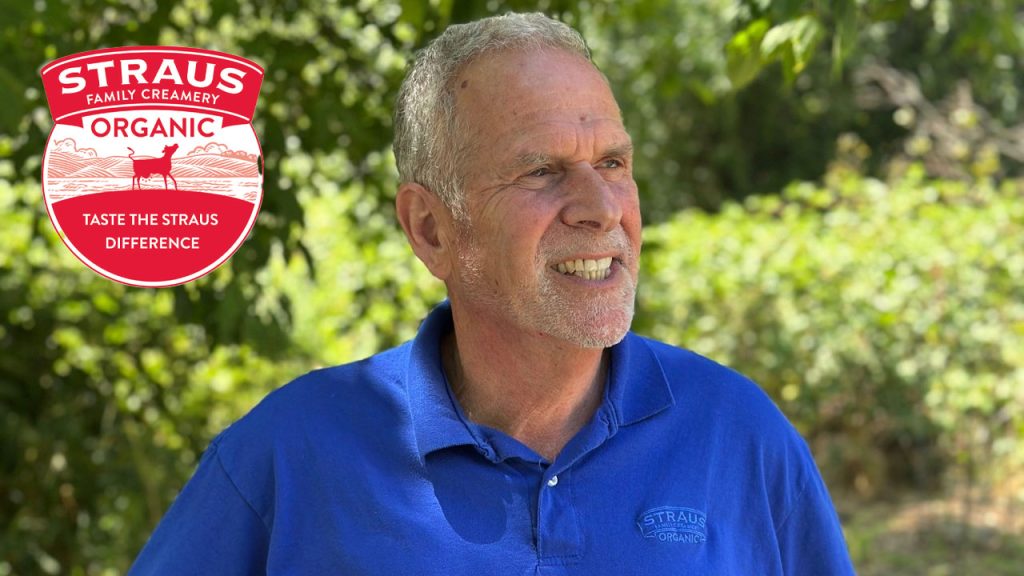

Albert Straus is the CEO of Straus Family Creamery, a mission-driven company launched in 1994. They have a deep commitment to supporting an organic dairy farming system that is both environmentally friendly and economically viable.

Albert shares a brief explanation of basic milk processing: “Cows produce whole milk with two components: nonfat milk and cream. Left to settle, the cream naturally rises to the top. This is what happens in nature; then, before arriving on the market, most of the milks are ultra-pasteurized to increase shelf life, which involves ’cooking’ the milk at high temperature (at or above 280° F for at least 2 seconds). These more heavily processed milks forfeit flavor and nutritional integrity in their quest for a longer shelf life.”